Test equipment

for Aviation and Automotive Professionals – Ask us, we take up your challenge!

Since 1990

TAP GmbH

Tillmanns Anlagen und Prüftechnik

TAP GmbH was founded in 1990.

The employees dispose of experience for more than 30 years in design and manufacturing of test rigs.

The wide range of products includes testing systems for the development and quality assurance of single parts and complete units, such as test benches for engines, turbines, hydraulic units and air units.

Due to the readiness to constantly face new tasks, TAP GmbH is your competent partner regarding test systems; – regardless if you desire a test system to be newly designed, or to take advantage of our services.

Ask us – we take up your challenge!

OUR SERVICES

Engineering capabilities

The development of new test systems is not a matter of individuals. TAP operates in close cooperation with development institutes, high tech start-ups and also large industrial corporations.

If available, market established components are used. Internal developments will be arranged, if extensive improvements were identified.

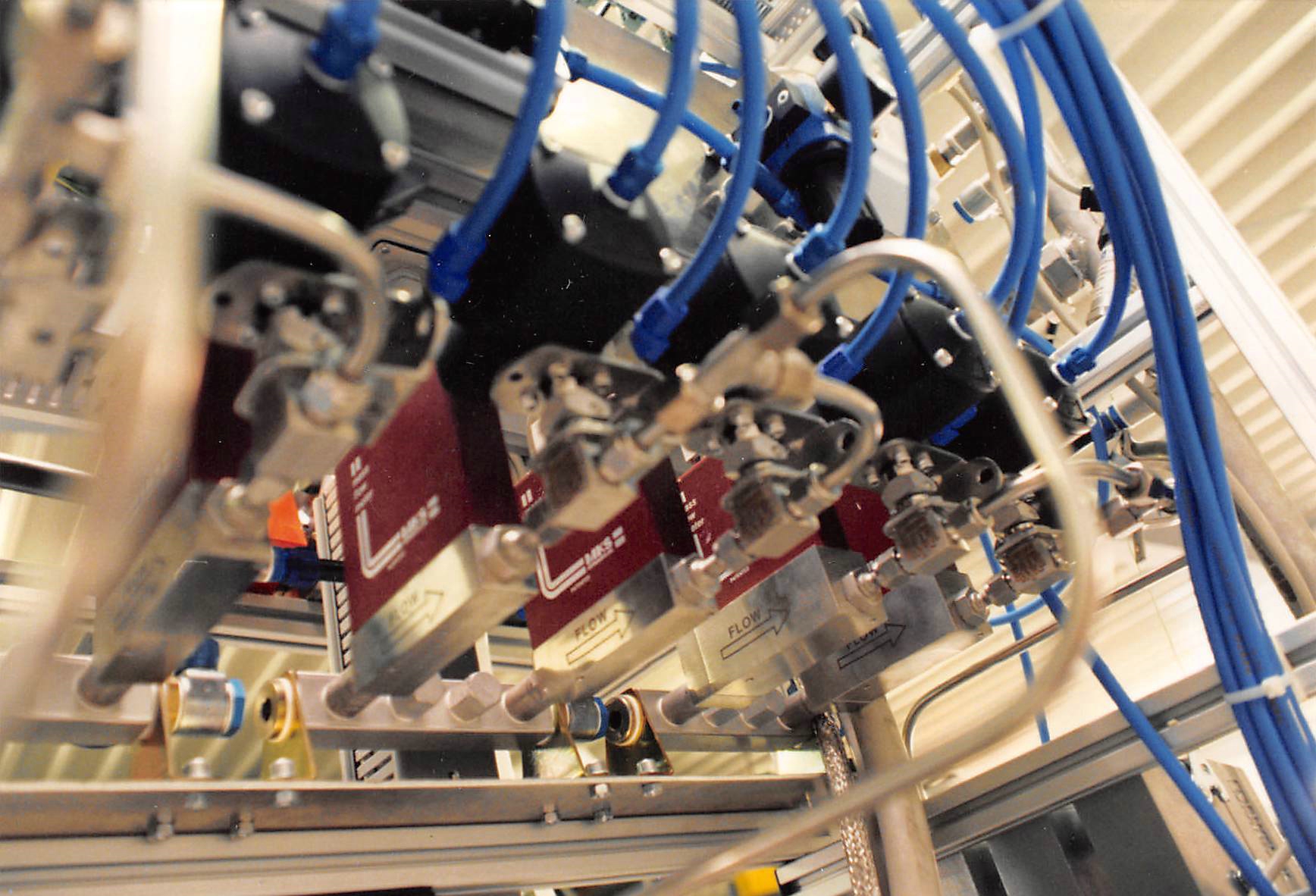

Airflow-rigs

Pressure and Vacuum Applications

- Pressure Range: -900 hPa til 16000 hPa

- Flowrates: 0,01 til 300 pph air

- high efficiency membrane dryers / high measuring accuracies

- universal worldwide electrical power connectivity;

- manually handled or automatic driven

- combination of application units

- special units for mobile service teams

Testing of actuators, valves, switches, checkvalves and nozzles

Actuator and Valve test benches

- pressure range: up to 40 bar

- flow range: up to 1600 lpmin

- high accuracy adjustment and measuring

- supply via shop air or nitrogen bottles

- optional: nitrogen Generator units

- data conditioning for use inside quality systems

Hydraulic Dynamometers / Dynamometer Controllers

As the technical representative of KAHN INDUSTRIES, a globally known manufacturer of hydraulic dynamometer systems, dynamometer controllers and engine test stands, TAP provides service, assistance and maintenance for units installed in Europe and Northern Africa.

The wide variety of the KAHN hydraulic dynamometer applications covers development and production testing of worldwide implemented APU’s , industrial gas turbines, steam turbines, turboprop and turboshaft engines.

Oilbath, Heatexchanger and explosion protected flushing testbenches

Oilbath and Heatexchanger

Heat exchangers have to undergo cleaning processes with hazardous and tempered fluids as well as mechanical vibrations to lose inner adherence. Multi-unit test fixtures ensure cost effective overhaul of these components.

Oil bath units ensure proper adjustment of temperature sensors and switches up to 400 °C

Closed cycle flushing units for gearboxes and components, acc. to actual ATEX provisions.

Fuel Components

- Universal fuel component test benches as well as special application e.g. for injection nozzle development.

- Injector flow check

- spray check and continuative analysis

- flow divider check

- Pressure chambers up to 100 bar counter pressure

Aircheck, Leakcheck & Tooling …

- compact mobile and case-integrated test units allow fast and easy checks of important system requirements

- These units are used for flow and leak checks on gearboxes, carbon seals or engine parts to ensure proper function

- Special formed adapters allow access to inaccessible connection points

- high volume / high temperature air supply systems up to 5000pph@500°C

Relocation and Modernisation

Planing and achievement of relocation from test equipment to another facility. After rebuilding, all test rigs undergo a complete start up procedure with measuring cycle calibration and correlation run with a unit that was tested before disassembly. Relocations were successfully performed on hydraulic test rigs, pneumatic test benches, robot welding machines, gearbox test rigs, shaft engine test benches.

Useful improvements and modernizations can be optional realized.